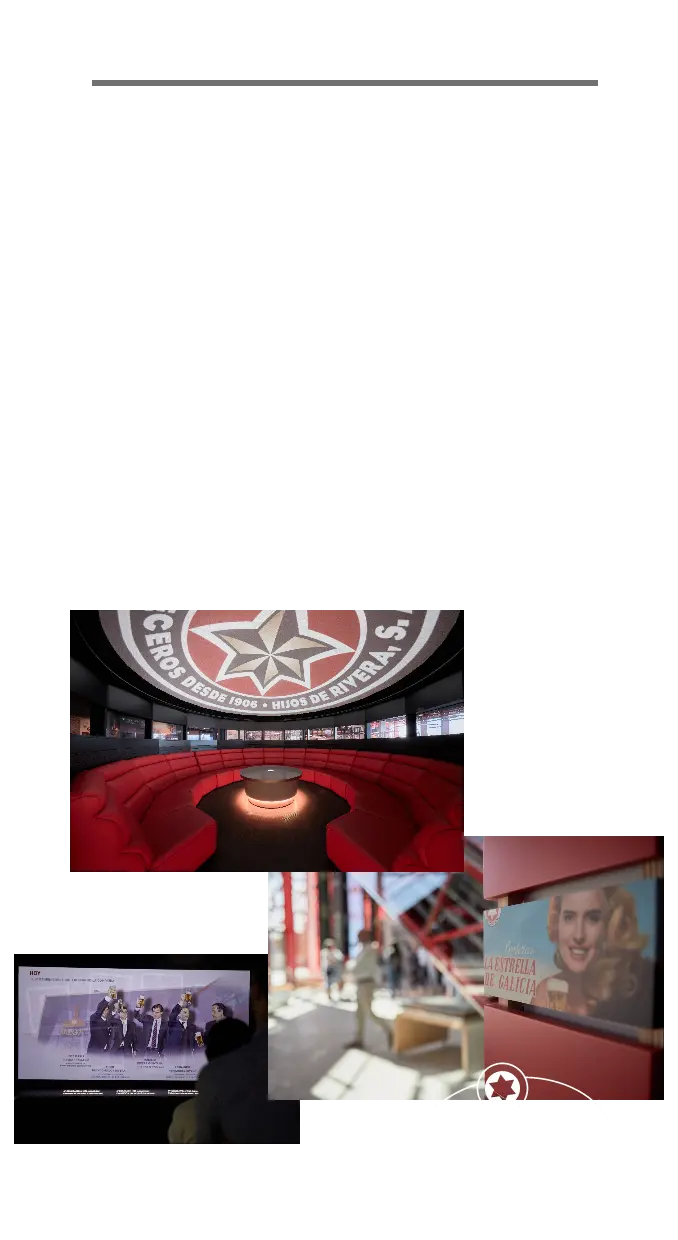

Vive la cerveza nivel mega

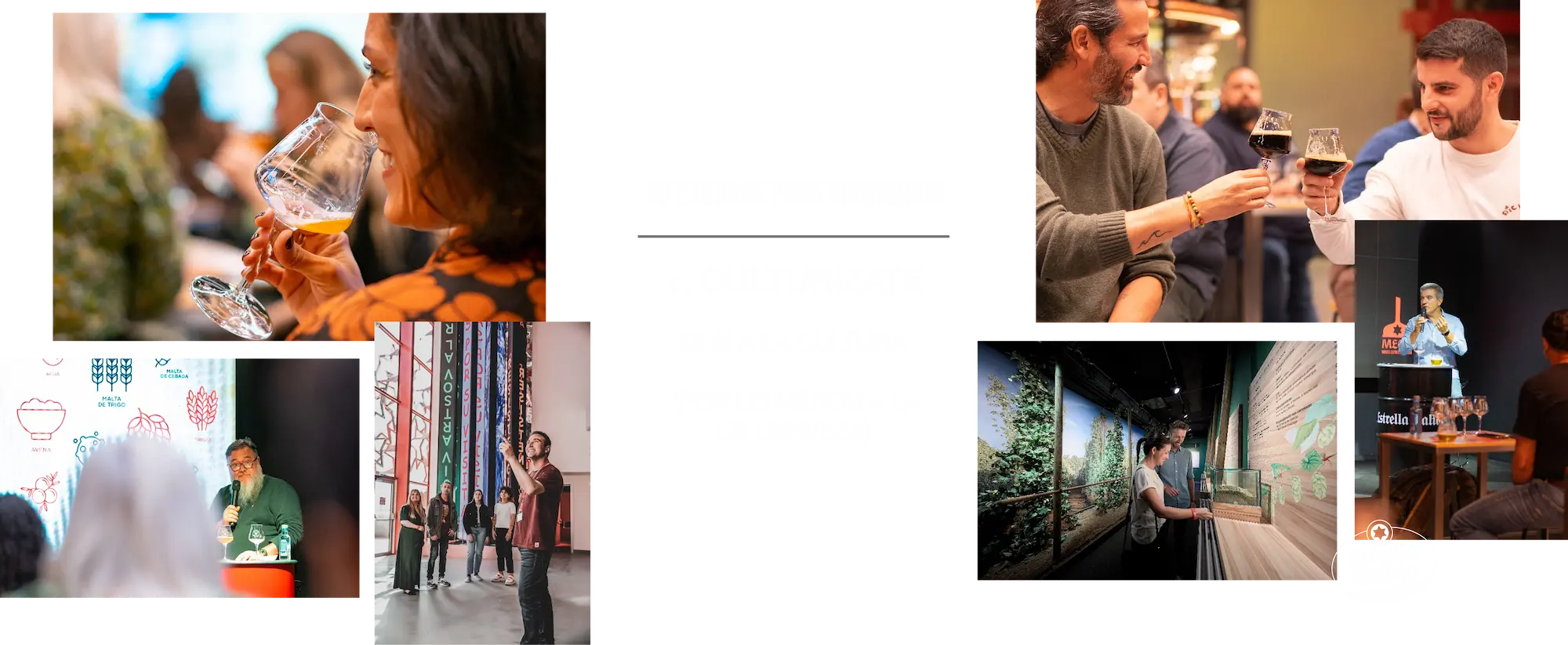

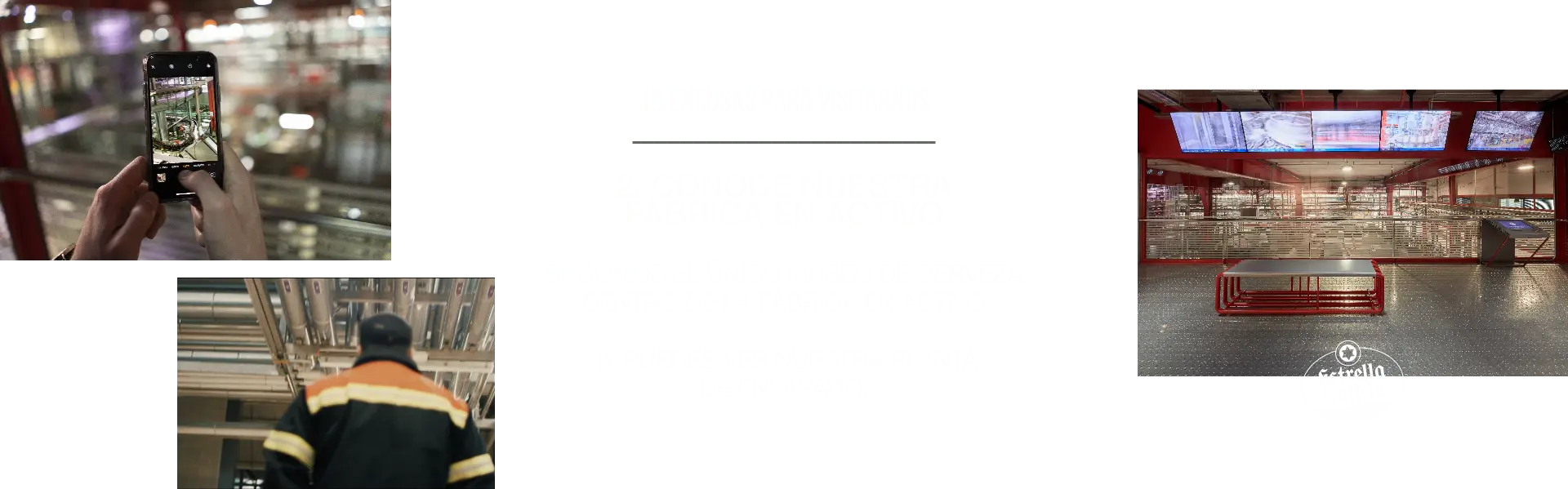

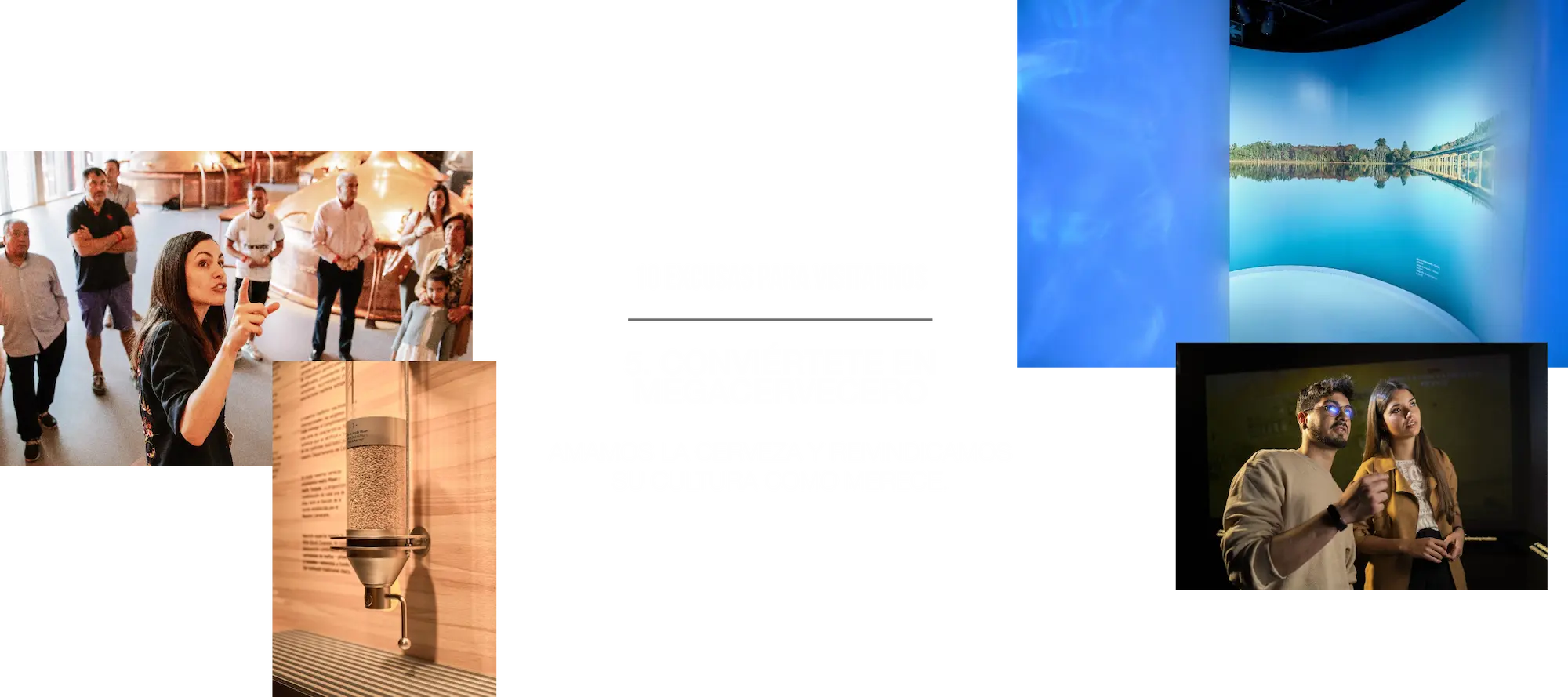

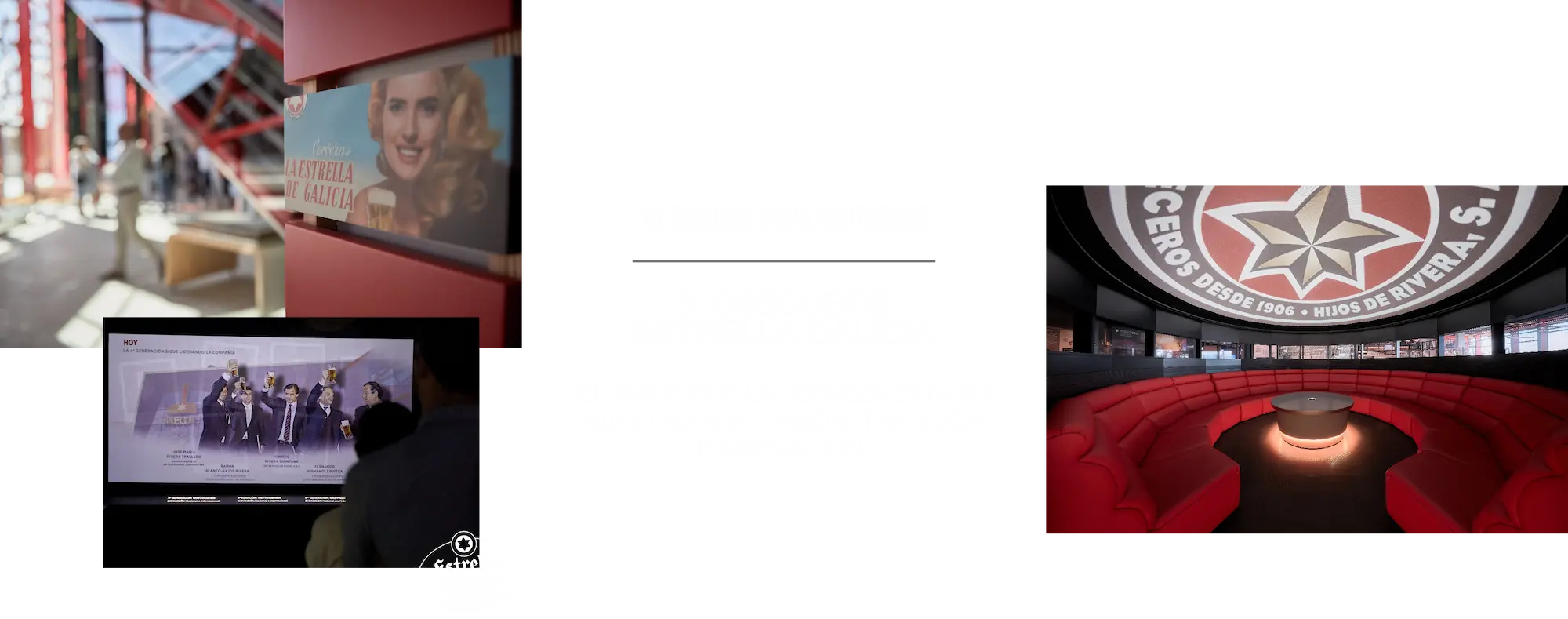

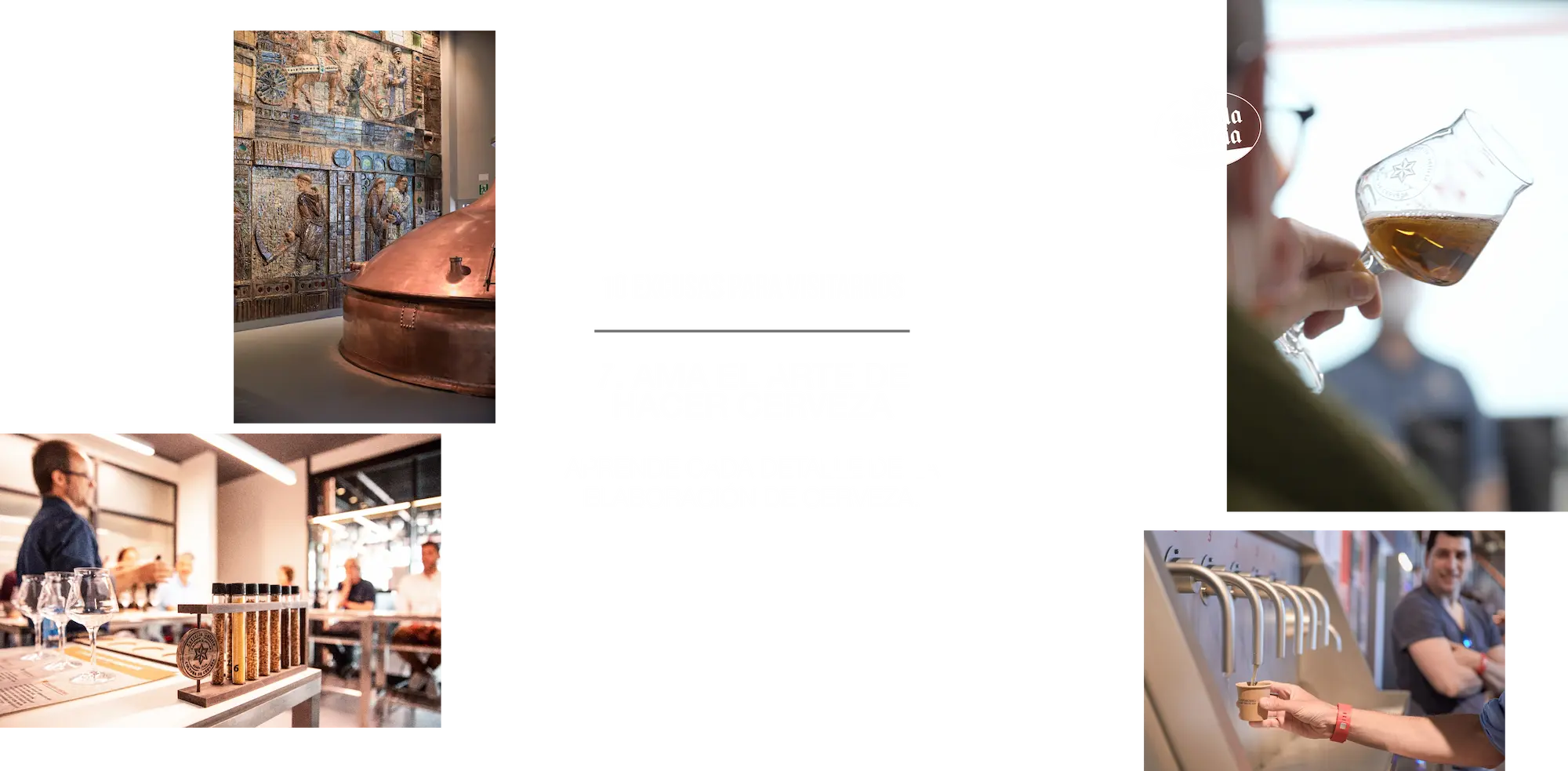

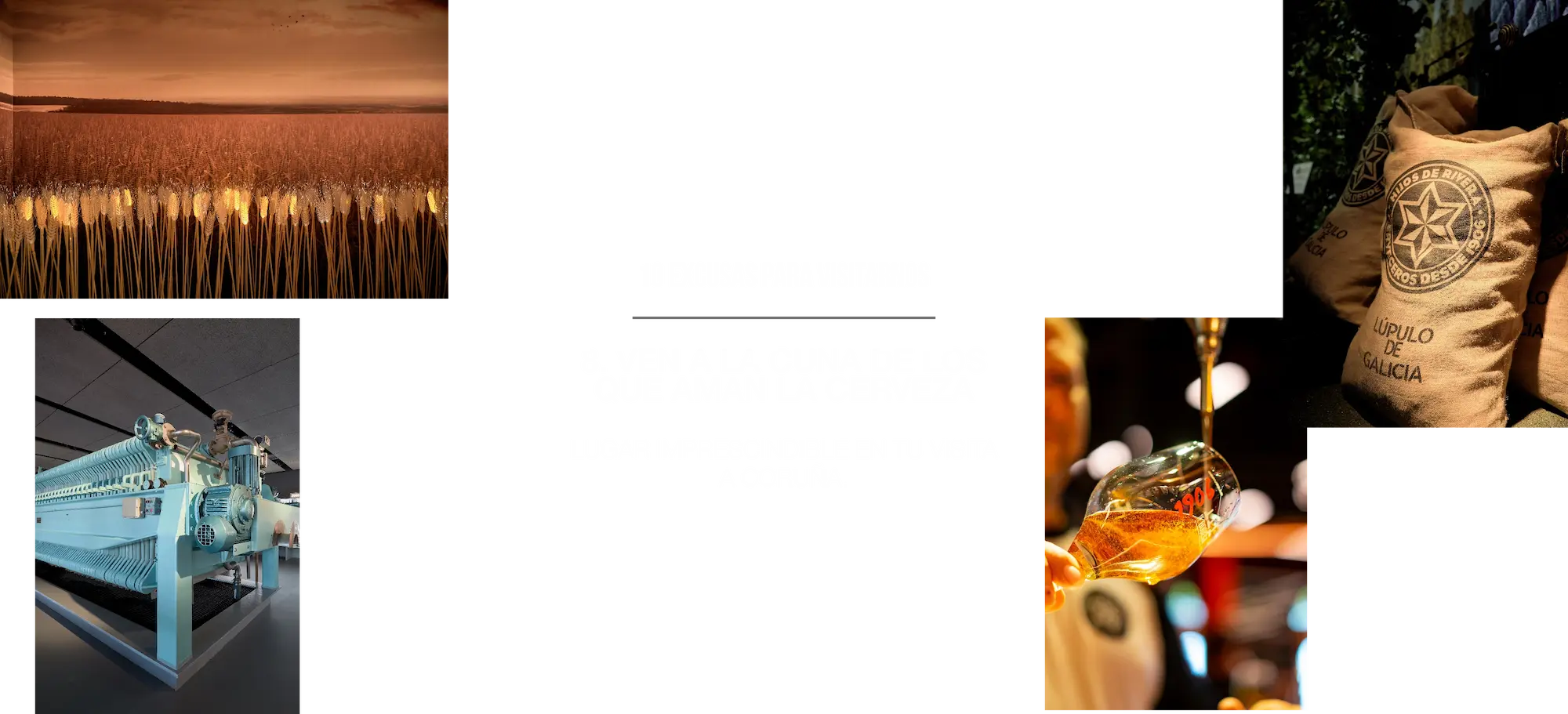

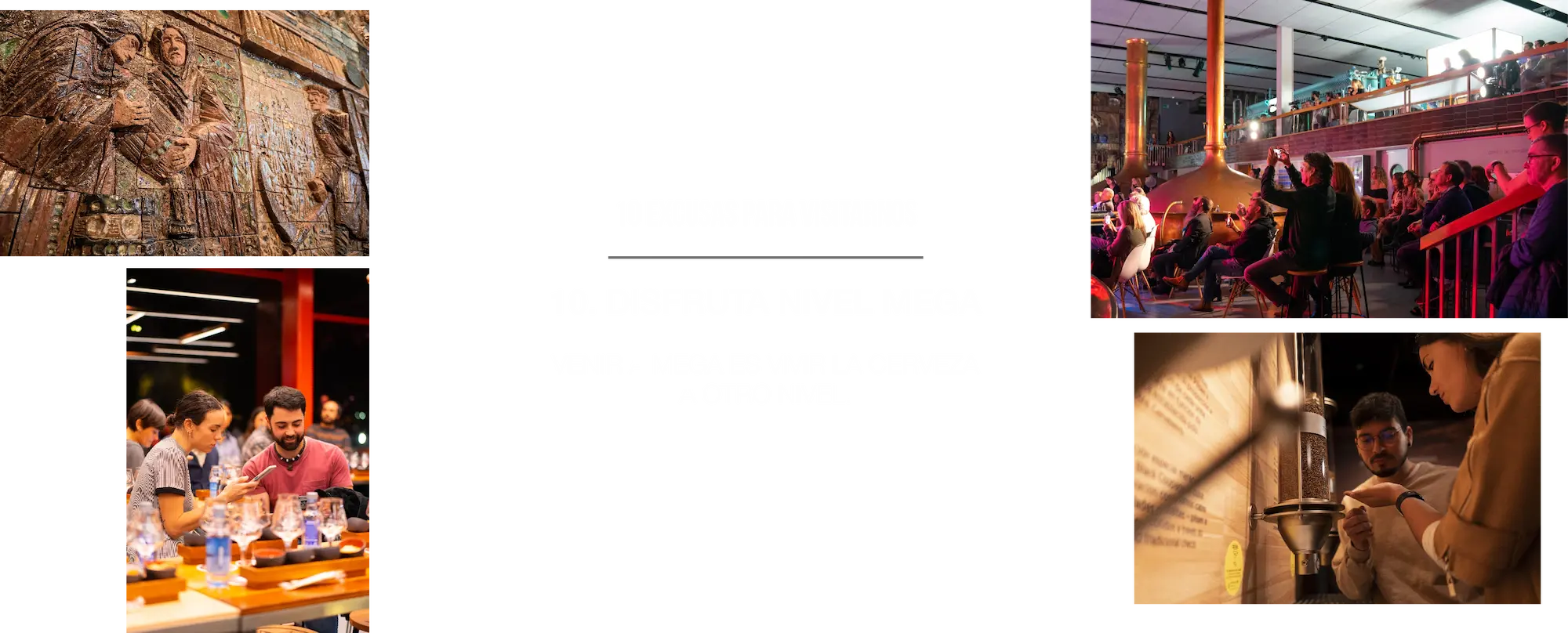

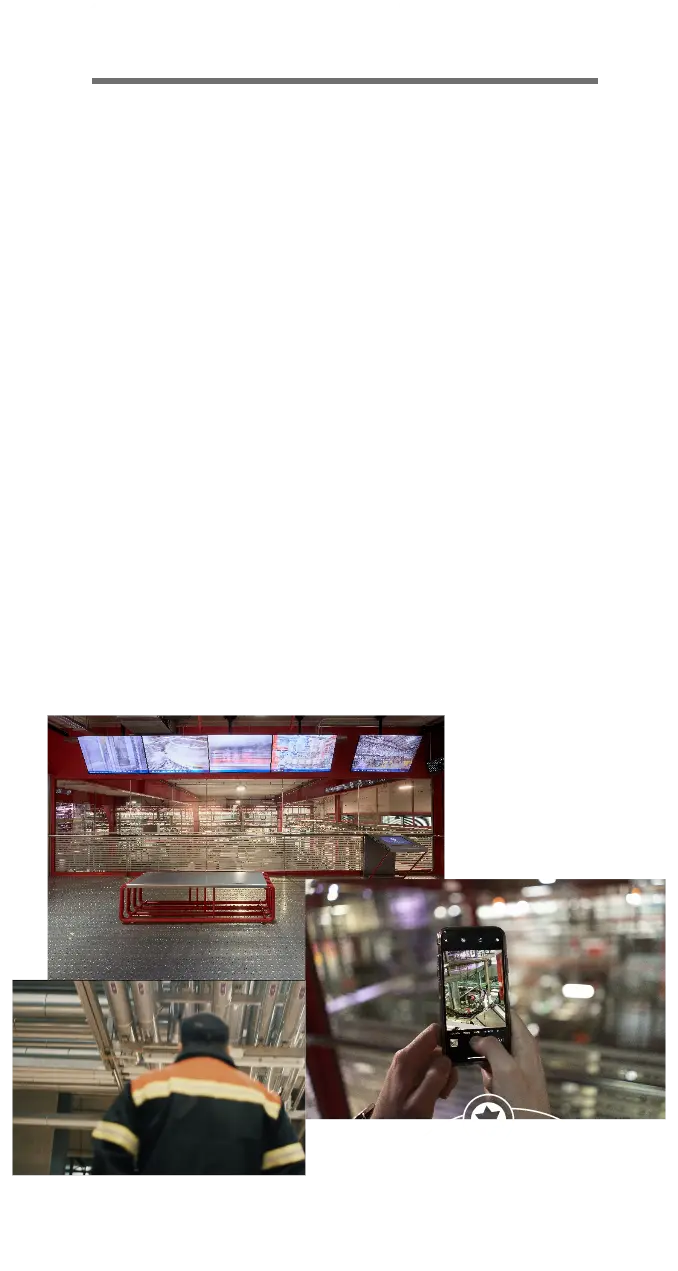

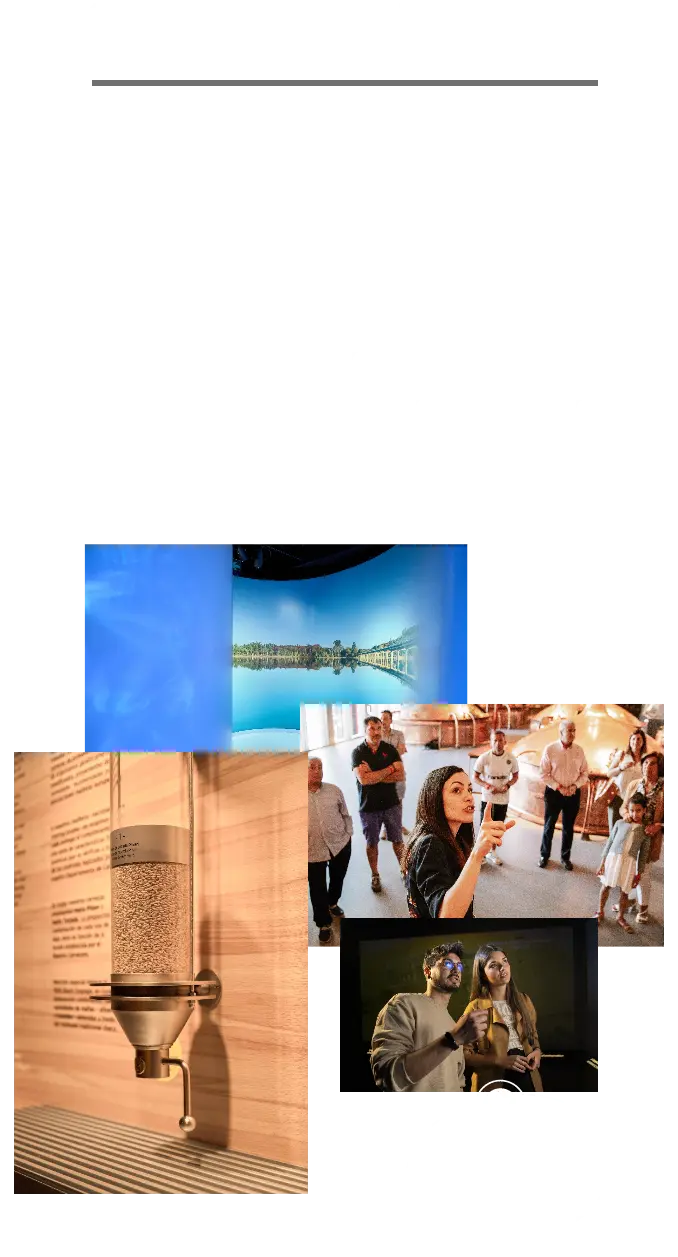

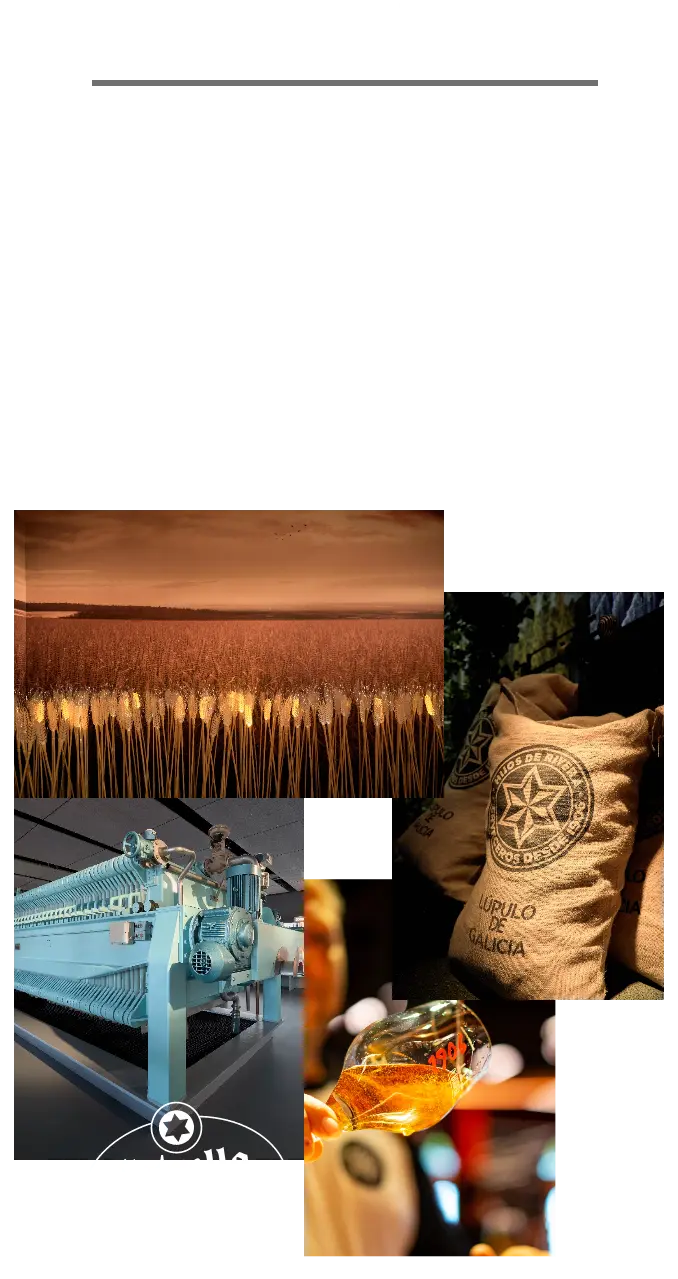

¿Preparado para vivir una experiencia cervecera interactiva, conocer el origen de Estrella Galicia y descubrir todos los secretos de la elaboración de Cerveza? Estás listo para visitar MEGA.

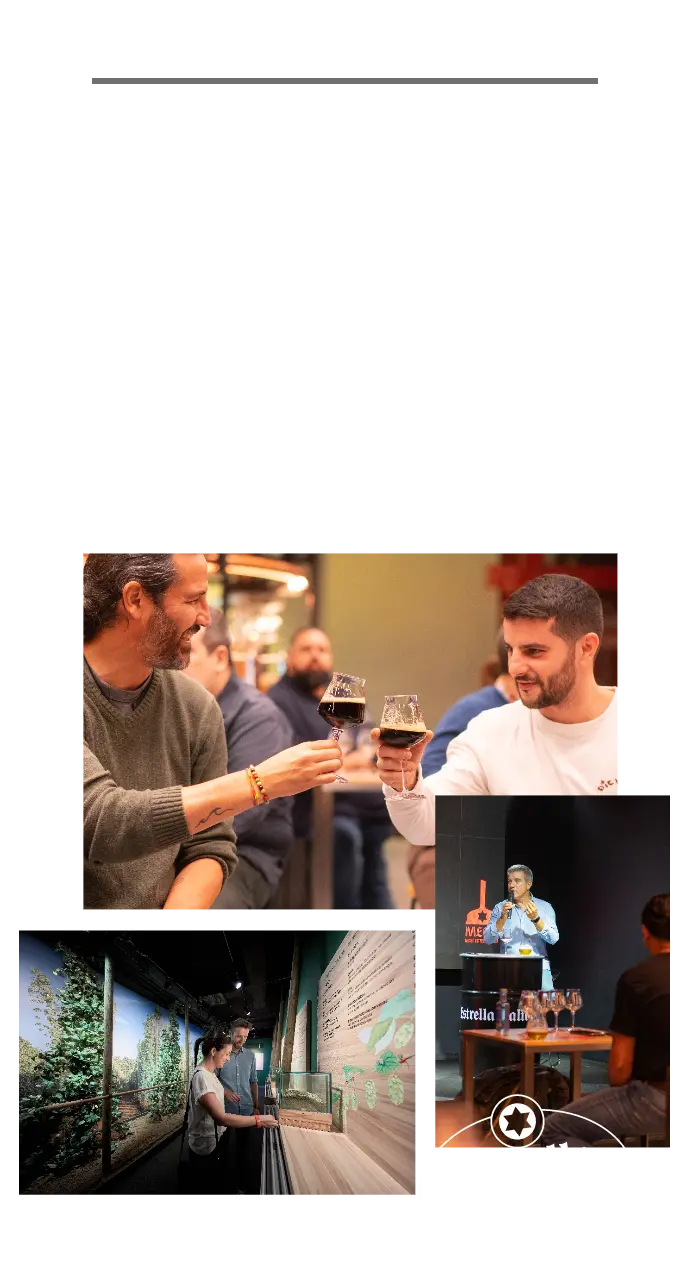

Guiada con Tiraje y Cata

Visita guiada

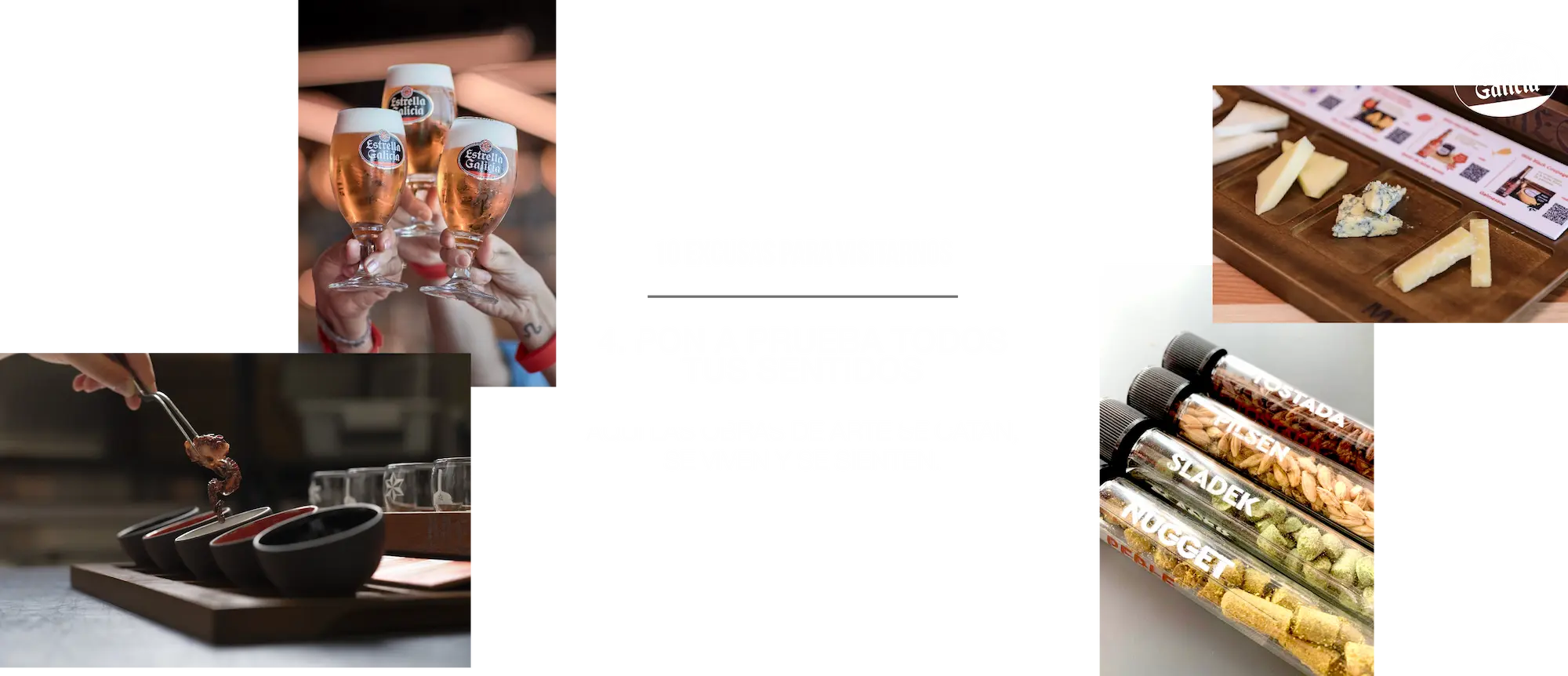

Tiraje de caña

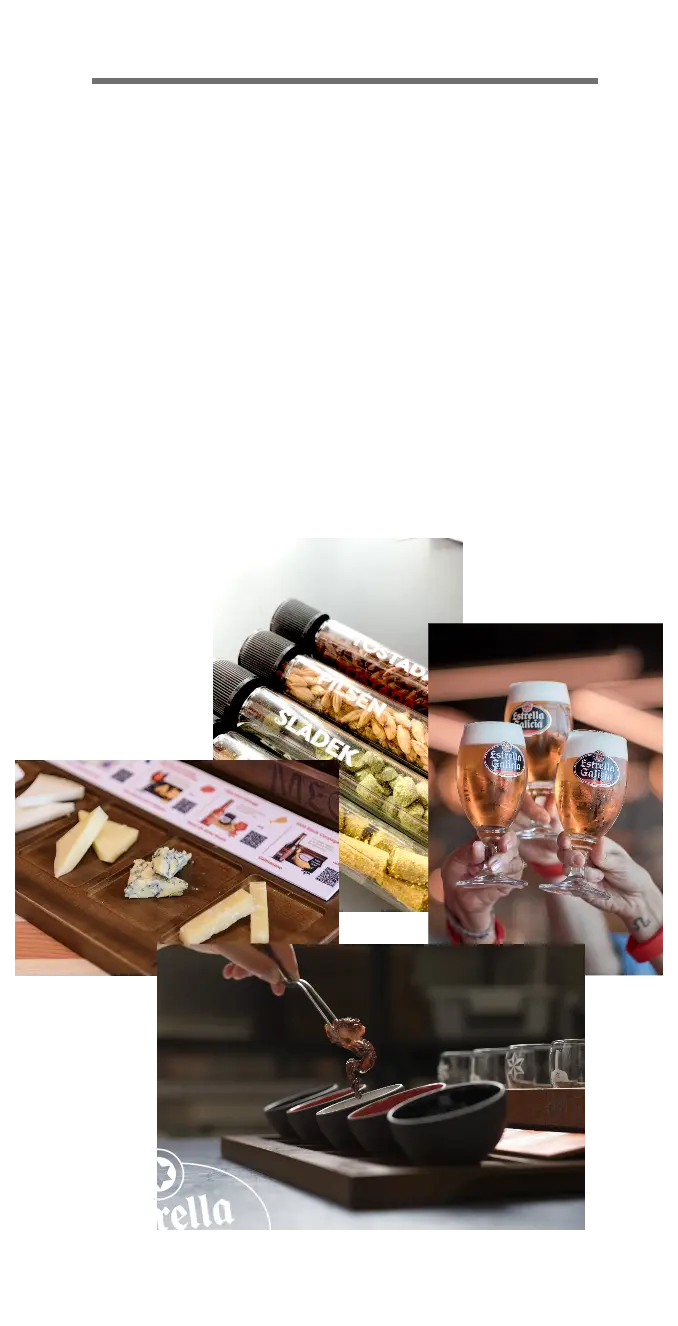

Set degustación

Taller de cata

Tiraje de caña

Set degustación

Taller de cata

Relax a la cerveza

Masaje Termaria

Visita guiada

Tiraje de caña

Set degustación

Visita guiada

Tiraje de caña

Set degustación

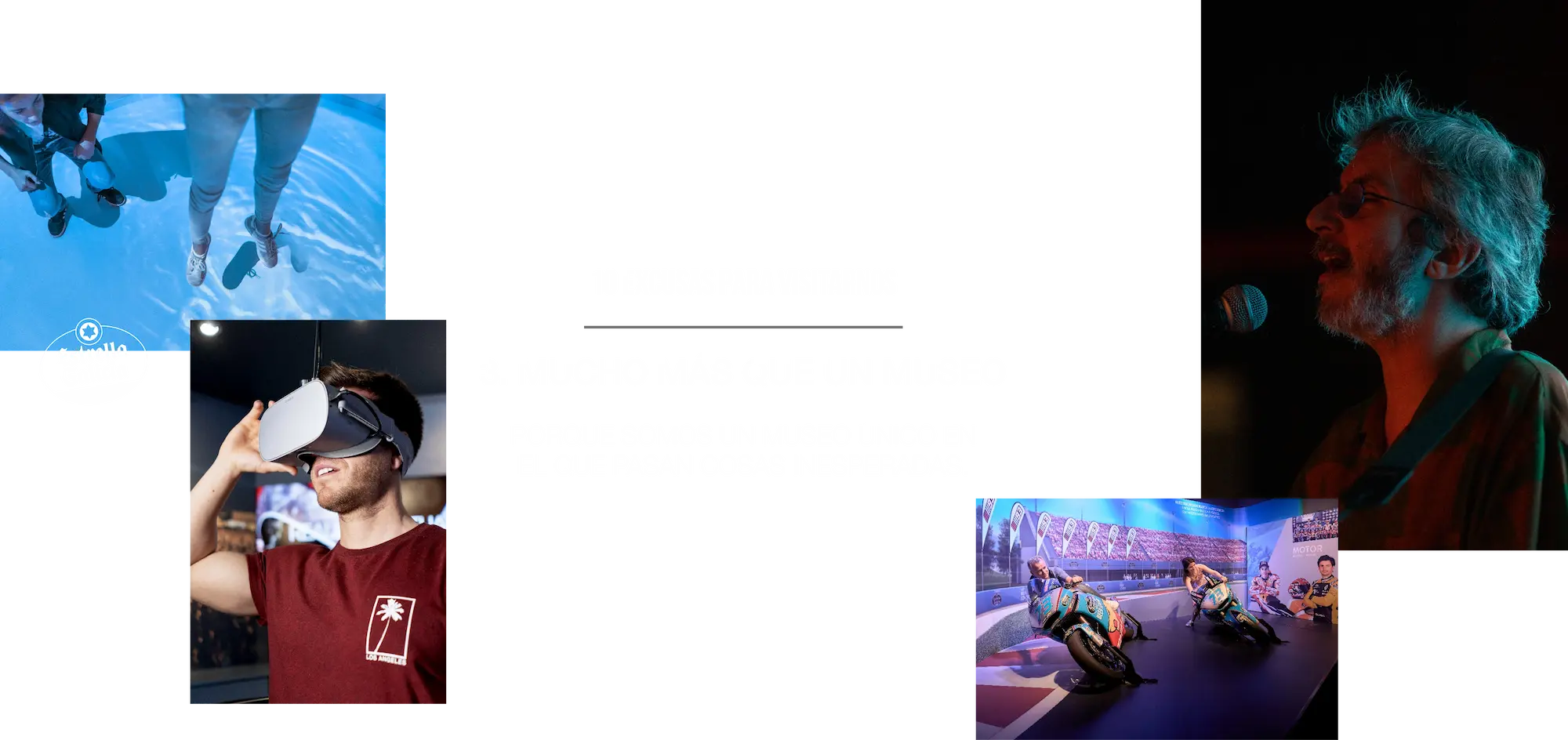

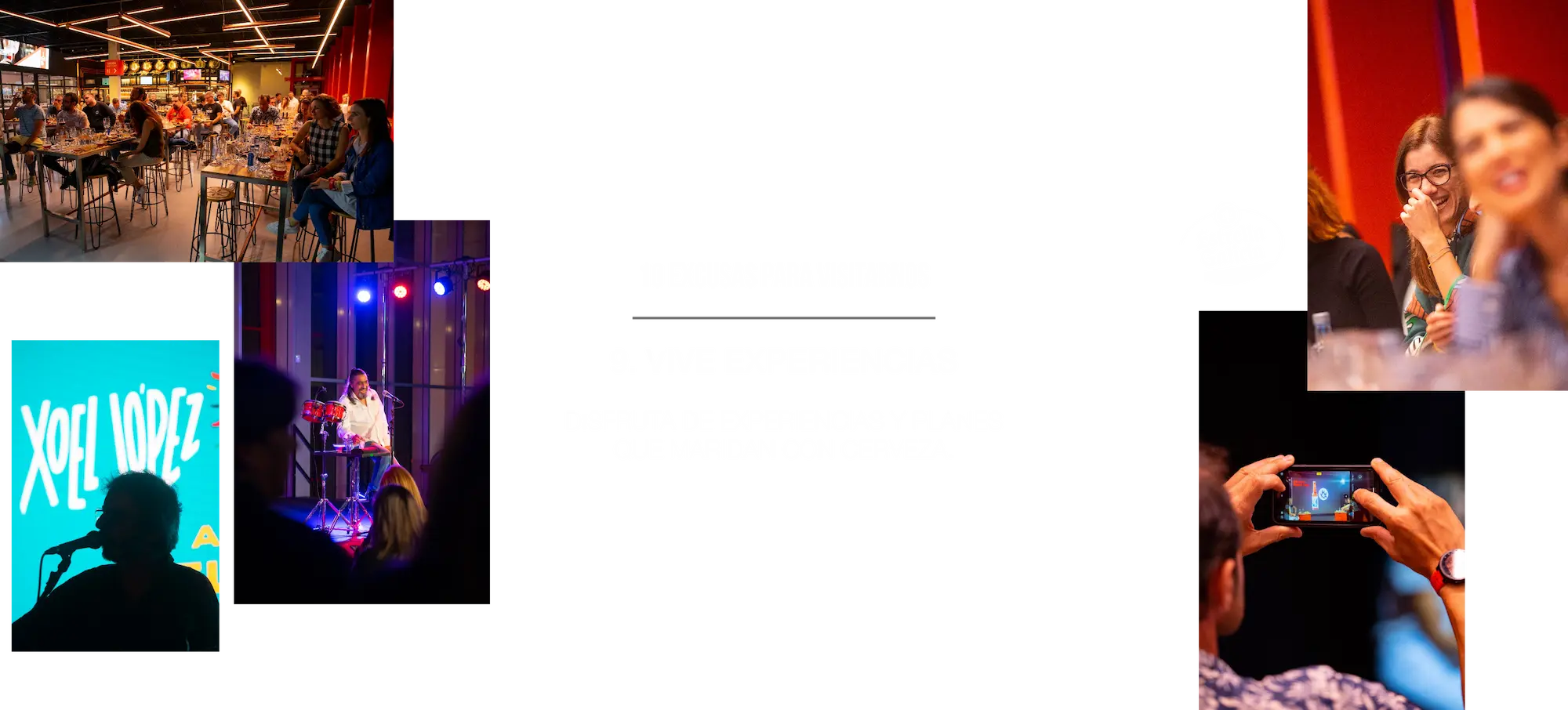

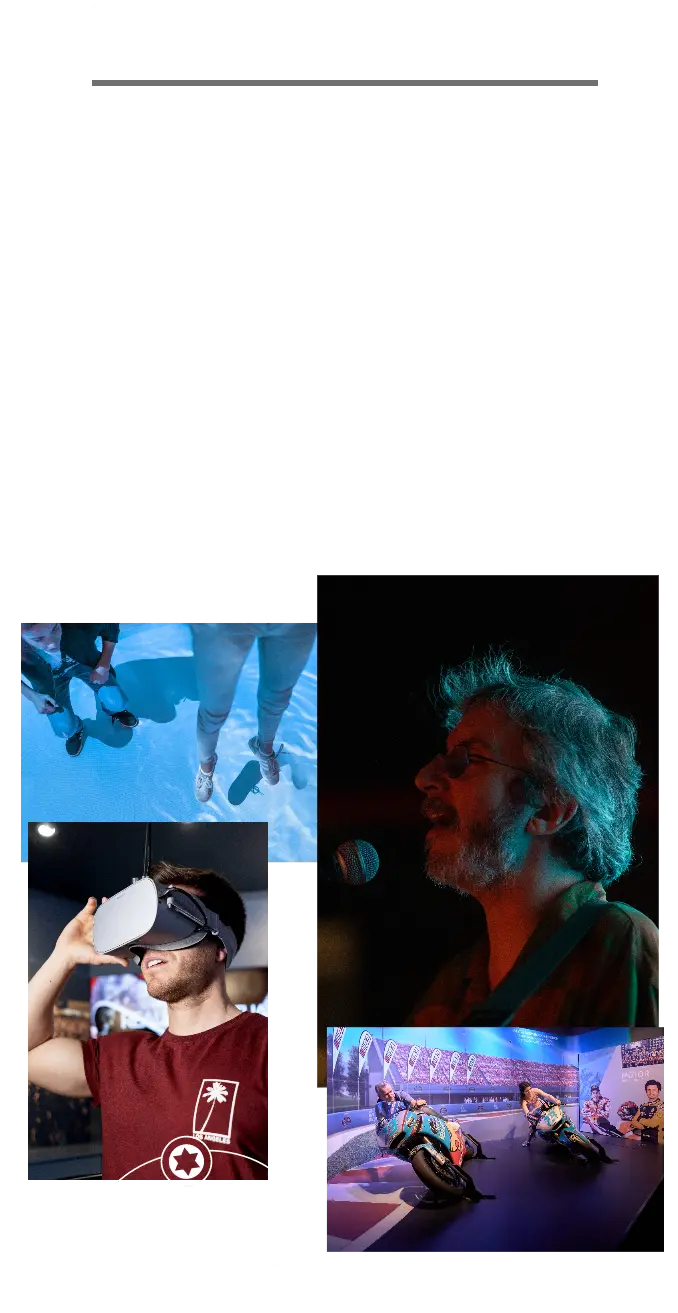

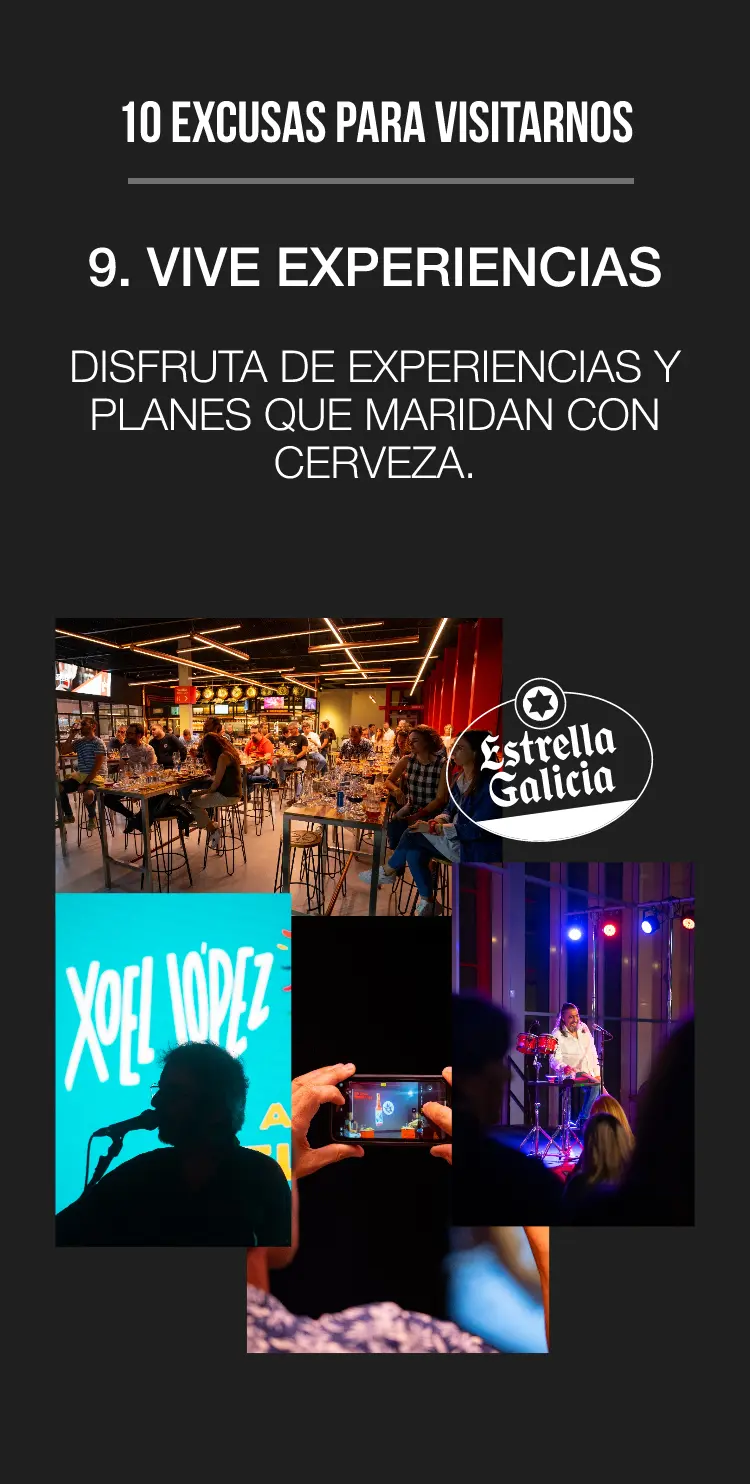

Planazos nivel Mega

¿Sabías que teníamos una agenda con auténticos planazos? Todos nuestros eventos tienen un noseque-queseyo que te hará vivir la cultura de cerveza a otro nivel. Apúntate al próximo y disfruta de experiencias gastro, conciertos increíbles, fiestas temáticas…

BLOG

Todo lo que necesitas saber sobre elaboración y cultura de cerveza